Views: 222 Author: Edvo Publish Time: 2025-11-07 Origin: Site

Content Menu

● What Are Heat Moldable Insoles?

● The Process: How to Mold Heat Moldable Insoles

>> Aftercare

● Scientific Basis: Why Custom Fit Matters

● Industry Use Cases: From Sports to Heavy Industry

>> Sports

● Materials and Manufacturing Techniques

>> Thermoplastics and Innovation

● Comparison: Heat Moldable vs Non-Moldable Insoles

● The Business Case for Heat Moldable Insoles

>> Why Add to Your Product Line?

● Choosing the Right Heat Moldable Insole Supplier

● Troubleshooting and Limitations

>> Solutions

● Environmental Considerations

● FAQ

>> 1. Are heat moldable insoles suitable for all types of shoes?

>> 2. Can I remold my heat moldable insoles if I'm unhappy with the fit?

>> 3. Do these insoles provide genuine medical benefits?

>> 4. How often should heat moldable insoles be replaced?

>> 5. Are there eco-friendly options available?

Heat moldable insoles are a transformative innovation in the world of footwear comfort, performance, and health. Designed to contour perfectly to the unique shape of each individual's feet, these insoles are especially attractive for athletes, workers, and consumers who demand superior fit and all-day support. As the trend toward personalization continues across industries, heat moldable insoles are carving a niche as an advanced solution for brands, wholesalers, and manufacturers intent on delivering greater value to international customers.

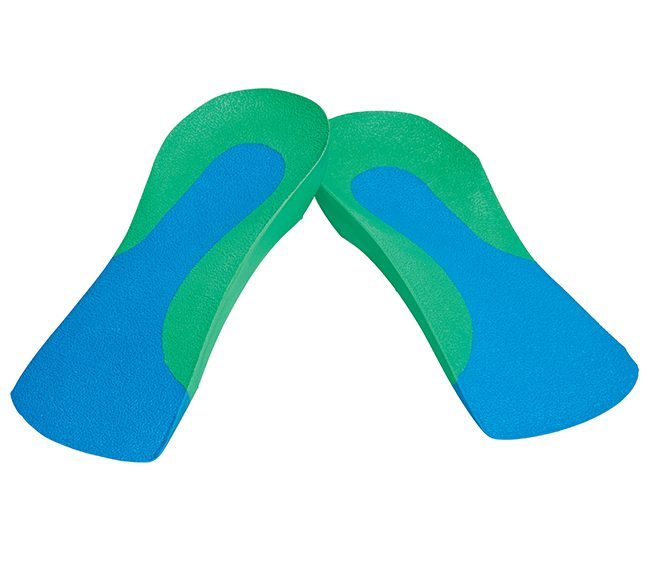

Heat moldable insoles are specialized footbeds that become flexible and shapeable when exposed to heat. Once warmed, these insoles adapt to the specific shape of your foot by using your body weight and natural standing stance. The result is a distinctive, tailored fit that enhances both comfort and performance.

Heat moldable insoles have found broad applications in:

- Athletic footwear, where custom fit enhances power transfer and reduces injury risk.

- Work boots, providing improved comfort, energy return, and reduced fatigue on long shifts.

- Orthopedic applications, helping correct gait and alleviate conditions like plantar fasciitis or chronic foot pain.

- Everyday footwear, offering a luxury feel to casual shoes and boots.

1. Preheat your oven to the manufacturer's recommended temperature—usually between 90°C and 115°C.

2. Insert the insoles and allow them to heat for two to three minutes.

3. Remove the softened insoles and quickly place them into your shoes.

4. Stand up straight in the shoes, allowing your weight to evenly mold the insole to your foot's shape.

5. Remain standing for several minutes until the insoles cool and firm up, locking in your personalized fit.

To maintain the insole's shape and effectiveness, avoid subjecting them to excessive heat after the molding process, and always follow cleaning and maintenance instructions from your manufacturer.

Standard insoles are designed for the “average” foot, but feet are as distinct as fingerprints. Heat moldable insoles compensate for this variability by providing individual alignment and cushioning. This personalized support reduces friction hot spots, prevents blisters, and allows arches—whether flat or highly pronounced—to receive the appropriate backing. Better support leads to less fatigue, especially over long distances or standing hours.

Foot alignment has ripple effects throughout the kinetic chain. By improving weight distribution and heel stability, heat moldable insoles can indirectly reduce stress on the knees, hips, and lower back. For sports professionals, even marginal improvements in alignment can translate to more effective sprints, jumps, and stops.

Elite athletes have long used custom orthotics to boost comfort and on-field effectiveness. Heat moldable insoles provide a semi-custom alternative at a fraction of the cost, making them accessible to recreational and competitive athletes alike. Runners and team sport athletes often report less foot soreness and improved feeling of stability.

For factory workers, construction staff, and those in logistics, foot fatigue is a common cause of musculoskeletal disorders. Custom-fit insoles distribute load more evenly and improve recovery, reducing absenteeism and injury rates in demanding work settings.

While true medical orthotics are still necessary for severe gait or structural issues, heat moldable insoles provide suitable first-line support for mild to moderate discomfort, heel pain, and arch problems, making them an attractive option for clinics and physiotherapy centers seeking affordable, scalable solutions.

The core of every heat moldable insole is thermoplastic EVA foam, known for its durable yet pliable nature. Some insoles incorporate polyurethane for added shock absorption and a plush feel, while others include antimicrobial overlays to control odor and bacteria formation. The layered construction process ensures each element works synergistically for comfort, longevity, and hygiene.

Our factory leverages advanced automation and stringent quality control measures. Automated vacuum-forming and precision cutting ensure consistency across high-volume orders. Private branding, anti-fraud serial tracking, and eco-friendly packaging options cater to every client's business and ethical needs.

- Heat moldable insoles adapt to a user's specific anatomy for maximum contact and support, while non-moldable insoles provide only generic levels of comfort.

- Moldable varieties can be reheated and adjusted two or three times, ensuring a forgiving fit process even for new users.

- Long-term comfort, decreased injury risk, and improved user satisfaction make heat moldable insoles a superior product for customers with above-average comfort and performance demands.

For brand owners and wholesalers, heat moldable insoles present a way to differentiate from commodity footbeds. Offering these insoles under private label not only improves product margins but also positions your brand as an innovator focused on real customer needs.

- Customization options, packaging, and online instructional resources can be bundled for a higher perceived value.

- These insoles can be marketed for sports, medical, or industrial use—tapping into multiple, lucrative market segments.

- Proven thermoplastic material quality and certifications.

- Transparent OEM/ODM capabilities, with custom branding and serialization.

- Flexible order quantities and responsive customer support.

- Willingness to supply product samples and technical support for overseas partners.

To extend the effectiveness and hygiene of your heat moldable insoles:

- Clean the surface gently by hand using mild soap—never soak or machine wash.

- Allow your insoles to air dry fully before reuse.

- Rotate pairs if wearing daily to preserve elasticity and structure.

Most users find that their insoles should be replaced every 6-12 months, though intensity of use and activity type will affect this timeline.

- Incompatibility: Extra-thick insoles may not fit some slim or formal footwear.

- Wear and Tear: Over time, heat moldable foam may compress and lose original shape, especially with intensive athletic or industrial use.

- Not a Replacement for Medical Orthotics: For serious biomechanical issues, prescription orthotics remain necessary.

Some advanced models now combine moldable layers with rigid arch supports or customizable heel elements, creating hybrid solutions that bridge the gap between off-the-shelf mall products and expensive custom orthotics.

Modern manufacturing trends have encouraged the use of recyclable and low-emission materials throughout the insole making process. Factories are increasingly focused on eco-friendly adhesives, liners, and packaging, responding to growing consumer and B2B demands for greener supply chains.

Heat moldable insoles deliver a truly personalized, comfortable, and adaptive solution for a diverse range of customers and industries. Properly manufactured and fitted, these insoles effectively blend the best of custom orthotics with the affordability and scalability B2B markets require. Whether integrated into athletic performance gear, heavy-duty workwear, or everyday shoes, they stand out in today's market for their real-world value, health benefits, and business potential for international partners seeking a competitive edge.

Yes, but very slim or formal shoes may not accommodate thicker insole profiles. Always check insole dimensions with shoe style to ensure compatibility.

Yes, most heat moldable insoles can be reheated and remolded a few times during their lifespan, according to manufacturer guidelines.

They offer substantial comfort and support and may relieve mild to moderate foot discomfort but are not substitutes for prescription orthotics in severe cases.

For everyday or heavy-duty use, replacing every 6-12 months maintains ideal support and hygiene.

Many brands and manufacturers now offer recyclable thermoplastic materials and liners, supporting more sustainable product lifecycles.