Content Menu

● What Are Super Sole Insoles?

● Top Manufacturers and OEM Suppliers

>> International Wholesale and Distribution

● Super Sole Insole Manufacturing Process

>> Cold Forming

>> Hot Pressing

>> Quality Assurance and Certification

● Customization, Branding, and Prototyping

>> Prototyping

● Popular Use Cases and Applications

>> Sports and Performance Footwear

>> Work Boots and Safety Shoes

>> Retail, Chain Stores, and Brands

● Innovative Material Technologies

● Sustainability and Eco-Friendly Options

● Bulk Global Distribution Strategies

● The Role of R&D in Performance Improvement

● Marketing and Launch Strategies for OEM Brands

● Industry Trends and Future Outlook

● FAQ

>> 1. What features make Super Sole Insoles different?

>> 2. Are Super Sole Insoles suitable for custom OEM branding?

>> 3. How can I purchase Super Sole Insoles in bulk?

>> 4. What are the best materials for Super Sole Insoles?

>> 5. How long does the OEM process take for new insoles?

Super Sole Insoles have become a leading solution for foot comfort and performance worldwide. They are popular among athletes, workers, outdoor enthusiasts, and everyday individuals seeking extra support and shock absorption in their footwear. Whether for sports, occupational safety, retail distribution, or private label branding, Super Sole Insoles represent a rapidly growing market segment. This article explores global sales channels, manufacturing processes, OEM/ODM possibilities, and strategic sourcing tips for brands, wholesalers, and retailers looking to expand business opportunities.

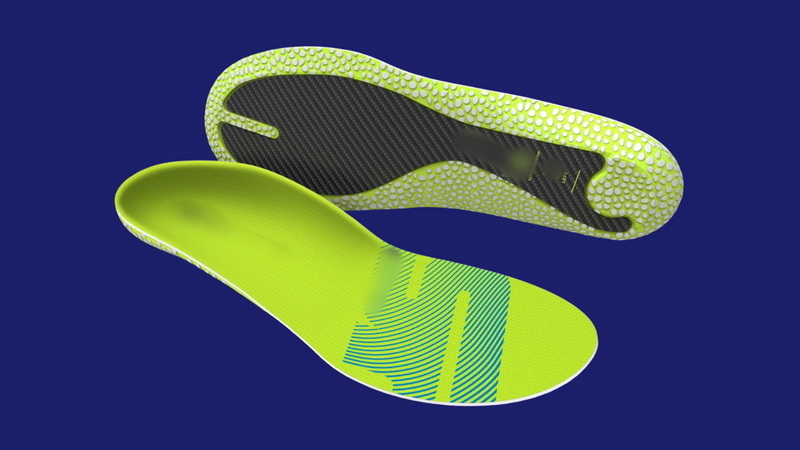

Super Sole Insoles are premium inserts for shoes designed to enhance comfort, foot health, and activity performance. Crafted from advanced materials—memory foam, EVA, PU, gel, and more—they provide superior cushioning and support. Their ergonomic design, moisture management, and odor control features cater to a variety of foot shapes and user needs.

- Adjustable arch support reduces the risk of foot fatigue.

- Shock absorption and rebound layers protect joints during high-impact activities.

- Breathable fabrics ensure dry, odorless feet for all-day wear.

Super Sole Insoles come in multiple styles to suit athletic shoes, work boots, casual sneakers, and even bespoke designer footwear. The versatility and performance make them ideal for OEM customization by brands, retailers, and distributors.

China stands as the global hub for insole manufacturing, renowned for robust production capacity, state-of-the-art facilities, and end-to-end OEM/ODM service. Chinese factories regularly partner with international brands to deliver custom solutions for every market segment.

These manufacturers use high-performance foams, polymers, and fabrics sourced from top global suppliers. Their R&D teams develop insoles tailored to customer specifications—brand logos, packaging, unique material blends, and functional upgrades like reinforced arch structures or antimicrobial coatings.

Global distributors and wholesalers rely on certified manufacturers to fulfill bulk orders, maintaining product quality while meeting tight delivery schedules. For retailers and chain stores, working with trusted producers ensures fast restocks, custom branding, and scalable SKUs.

- Custom solutions for bulk quantities enable brand differentiation.

- Retailers frequently secure exclusive designs and packaging.

- Wholesalers often benefit from lower minimum order quantities and tiered pricing.

Production of Super Sole Insoles involves advanced manufacturing techniques to guarantee consistency, durability, and performance. Modern insole factories operate with the following technologies:

Cold forming is widely used for medium-hard EVA and POLIYOU insoles. Pre-cut sheets are softened in ovens, quickly placed in precision molds, and then subjected to controlled compression and cooling cycles. This process delivers high yield and excellent material integrity—a must for high-volume supply.

Higher technical requirements, especially for firm and orthopedic variants, employ hot press molding. Sheet materials are heated and shaped under pressure, followed by rapid cooling. This process creates rigid insoles with advanced support features, making them suitable for demanding users and environments.

PU-based Super Sole Insoles often use injection molding. The middle part of the insole is fabricated first, set in a mold, and then filled with PU materials to form the outer margin. This ensures that ergonomic design features like multi-layer cushioning integrate seamlessly into the final product. Injection molding is essential for complex designs requiring distinct zones of support, softness, or breathability.

Advanced insoles utilize multi-layer construction. Glass fiber or reinforced cloth layers are impregnated with resin mixtures, then cut to precise shapes. These composite sheets are assembled with foam, gel, or PU layers and heat-pressed in molds. Fabrics or leathers are brushed or laminated onto the surface, adding durability and style.

During assembly, manufacturers may integrate specialized components such as PORON heel pads, TPU arch support films, moisture-wicking meshes, or anti-microbial agents. Together, these enhancements elevate ergonomics, comfort, and hygiene for the end user.

After molding and assembly, insoles undergo rigorous quality checks—dimensional accuracy, compression resistance, flex tests, and microbial safety evaluation. Certified production facilities often hold ISO, CE, and industry-specific certifications, assuring international buyers of compliance and consistent standards.

OEM and ODM service providers guide clients through design, sampling, and prototyping stages before mass production. Brands can achieve their desired look and feel with custom colors, logos, packaging, and even unique material combinations.

Before full-scale production, rapid prototyping via 3D printing or small-batch molds allows brands to test ergonomic fit, durability, and aesthetic appeal. Adjustments are made to optimize cushioning, support zones, and sew-in or print options for brand identity.

Customized packaging—from branded retail boxes to private label blister packs—supports product launches and retail promotion. High-quality packaging reinforces perceived value and distinguishes Super Sole Insoles on crowded shelves.

Super Sole Insoles are a staple in athletic shoes, elevating comfort, reducing injury risk, and enabling peak performance. Orthotic models provide rigid arch support, while flexible variants offer responsive rebound for running, hiking, and general fitness.

- Lightweight foams dissipate impact for runners and basketball players.

- Breathable mesh keeps feet dry during intense activities.

- Custom sports insoles improve alignment and energy return.

Occupational users appreciate Super Sole Insoles for their ability to alleviate fatigue and prevent foot pain during long shifts.

- Heavy-duty insoles cushion feet against concrete and industrial surfaces.

- Reinforced shanks support balance and posture for construction workers.

- Anti-slip materials ensure secure footing in hazardous environments.

Store owners, supermarkets, and e-commerce retailers often feature branded insole lines, packaged for easy browsing and impulse buys. Exclusive OEM designs differentiate their catalog, attract repeat customers, and offer strong margins.

- In-store displays promote new arrivals and seasonal specials.

- VIP brands can bundle insoles with premium footwear for value-added campaigns.

Professional buyers should evaluate several factors when selecting a Super Sole Insole partner:

- Experience and R&D strength

- Material sourcing and environmental compliance

- Customization process and prototyping capabilities

- Minimum order quantity and delivery reliability

- QA/QC protocols and after-sales service

Long-standing partnerships allow scalability and enable ongoing refinement of product features, materials, and branding.

Modern Super Sole Insoles draw on a wealth of material advancements:

- Memory foam: adapts to foot contours, evenly distributing pressure

- EVA: known for its lightweight qualities and excellent shock absorption

- PU: delivers long-lasting durability and higher resistance to flattening

- Gel: softens high-impact zones such as heels and forefoots

- Open-cell foam: encourages airflow and prevents microbial buildup

Evolving technologies now allow for blends and multi-layer systems, delivering precise support, moisture management, and lasting comfort.

As consumer awareness grows, many manufacturers are investing in sustainable production. Options include:

- Recycled foam and fabric

- Water-based adhesives

- Eco-safe dyes and treatments

These green alternatives cater to environmentally conscious brands and retail programs seeking to minimize their carbon footprint.

International buyers can leverage trade platforms, distribution networks, and direct factory relationships to acquire Super Sole Insoles at scale. Secure payment terms, transparent logistics, and product tracking contribute to reliable business continuity.

- Online B2B portals aggregate verified suppliers and streamline sourcing processes.

- Buyers can request free samples, negotiate order volumes, and customize logistics to maximize cost efficiency.

Bulk purchasing benefits include preferential rates, streamlined freight management, and improved inventory planning.

Leading Super Sole Insole producers invest heavily in research and development. Their laboratories test foam density, resilience, and compression rates. Dedicated biomechanical engineers analyze plantar pressure distribution to optimize geometry. Advanced CAD modeling and material sciences ensure that every new generation of insoles delivers measurable improvement in comfort and biomechanical support.

New product launches succeed on clarity of messaging and visual identity. Brands develop compelling marketing campaigns utilizing influencers, athletic sponsorships, in-store demos, and digital advertising. Powerful storytelling—showing how Super Sole Insoles transform user comfort and performance—cuts through market clutter and drives sales velocity.

Brands also capitalize on e-commerce by providing detailed product listings, high-quality images, and instructional videos demonstrating fit and features. User reviews and testimonials further establish trust and credibility.

The global insole market grows steadily, driven by rising health awareness, technical innovation, and expanding e-commerce. Future trends may include:

- Adaptive and smart insoles using sensors to track movement and detect fatigue

- Integration with health apps for personalized recommendations

- Expansion of sustainable materials and closed-loop manufacturing

As competition intensifies, continuous product innovation and strategic supplier relationships will remain key success factors.

Super Sole Insoles are distributed worldwide by top-tier manufacturers, OEM suppliers, dedicated wholesalers, and chain retailers. Modern production methods and customization options enable brands and distributors to launch highly differentiated product lines. With advanced ergonomic features, durable materials, and tailored support for various user needs, Super Sole Insoles deliver exceptional value and comfort to customers everywhere. When sourcing, prioritize supplier experience, R&D capabilities, and flexible OEM solutions to establish a competitive edge in the footwear market.

Super Sole Insoles offer advanced ergonomic design, superior shock absorption, excellent moisture management, and multiple customization options for brands and retailers.

Yes, most leading manufacturers provide full OEM services, from prototyping and branding to packaging customization, enabling retailers and brands to establish unique insole products.

You can source Super Sole Insoles via trade platforms, certified factories, or direct B2B supplier relationships, arranging for custom specifications and convenient bulk order fulfillment.

Top materials include memory foam, EVA, PU, gel, and open-cell foam—all chosen for their cushioning, durability, and hygiene benefits.

Standard production lead times range from prototype approval to mass production, typically spanning several weeks. Efficient suppliers offer rapid turnaround and global shipping.