Views: 222 Author: Edvo Publish Time: 2025-10-18 Origin: Site

Content Menu

● The Rise of EVA Insoles in Footwear Manufacturing

>> Key Features of EVA Insoles

● The Portuguese Footwear Ecosystem

>> Benefits of Sourcing in Portugal

● Profiles of Leading EVA Insole Manufacturers and Suppliers in Portugal

>> Faplana Footwear Components

>> Additional Specialists and Growing Suppliers

● OEM and ODM Services: Adding Value for Global Brands

● The Importance of Material Selection and Performance Testing

● Integrating Chinese Manufacturing for Global Competitiveness

● Industry Trends: Sustainability, Smart Features, and Market Expansion

>> Green Manufacturing and Circular Economy

>> Smart Insoles and Digital Integration

>> New Market Segments and Customization

● How to Choose Reliable Eva Insole Manufacturers and Suppliers

● From Inquiry to Delivery: Working with Portuguese Suppliers

● FAQs

>> 1. What makes EVA the preferred material for insoles?

>> 2. Are Portuguese manufacturers able to produce custom EVA insoles for unique shoe designs?

>> 3. How do I assess the quality of EVA insoles from a new supplier?

>> 4. Is it possible to source eco-friendly or recycled EVA insoles?

>> 5. How long does it typically take to produce and deliver OEM EVA insoles from Portugal?

Footwear comfort and performance are intimately linked to the quality of insoles. Over recent years, Ethylene Vinyl Acetate (EVA) has risen to prominence as the insole material of choice due to its lightweight properties, superior cushioning, and remarkable durability. Portugal, with its long-established footwear tradition, has become a hub for advanced insole production. The country's leading factories and component suppliers play a vital role in global supply chains, providing custom and standard products to brands, wholesalers, and manufacturers worldwide. In this guide, we present an in-depth look at the top Eva Insole Manufacturers and Suppliers in Portugal, examining their production capabilities, OEM advantages, and the broader trends shaping the industry.

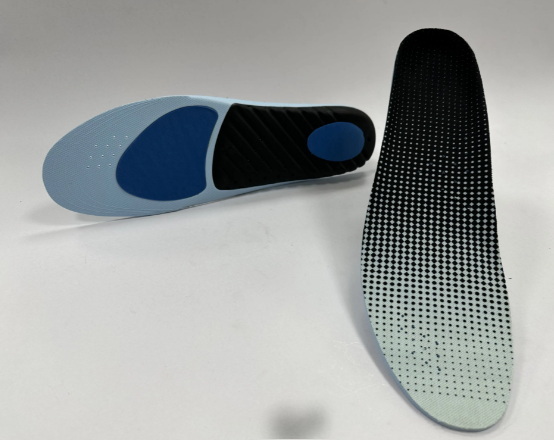

Ethylene Vinyl Acetate, commonly known as EVA, is a closed-cell foam renowned for its shock absorption, flexibility, and versatility. Modern footwear designers depend heavily on EVA components because they allow for highly customizable fit and performance. Whether used in running shoes, orthopedic boots, or everyday casual footwear, EVA insoles help reduce fatigue, prevent injuries, and maximize user satisfaction.

- Exceptional Comfort: EVA's cushioning effect absorbs shocks from daily walking or energetic sports activity, minimizing joint stress.

- Lightness and Flexibility: EVA materials contribute little to shoe weight, allowing for lighter, more comfortable styles.

- Durability: Quality EVA remains consistent in shape and function after long-term use, resisting compression and deformation.

- Moisture and Odor Resistance: Closed-cell structure blocks water and impedes microbial growth, key for maintaining hygiene.

- Customizability: EVA is easily colored, shaped, and branded, which benefits both custom OEM projects and mass OEM production.

Given these advantages, demand for experienced Eva Insole Manufacturers and Suppliers has intensified, with Portuguese factories leading innovation.

Portugal's reputation as a European footwear center is underpinned by centuries of craftsmanship and strong integration with global markets. Its manufacturers blend artisanal skills with cutting-edge automation, providing highly consistent quality. Portugal's key footwear regions—Porto, Felgueiras, São João da Madeira, and Braga—are home to a dense concentration of insole and shoe component specialists.

- Proximity to EU markets: Reduced transit times and simplified compliance with European regulations.

- Stringent quality standards: Portuguese suppliers are subject to rigorous product testing and certification.

- Flexibility and responsiveness: Factories support both low and high minimum order quantities and adapt quickly to fashion trends.

Portugal's strong export orientation makes it especially attractive for overseas brands looking for reliable Eva Insole Manufacturers and Suppliers who are familiar with international shipping, quality assurance, and communication standards.

Faplana is renowned for collaborating with leading shoe brands across Europe. The company utilizes precision CNC cutting and multi-density EVA compounds, providing components for fashion, sports, and medical footwear sectors. Faplana emphasizes custom development: their R&D experts frequently co-design insoles with client engineering teams for optimized fit and performance.

Procalçado is a diversified footwear components group, producing not only insoles but also soles and rubber parts. Their specialized EVA division offers advanced footbed solutions and customized branding—including color, logo, and packaging options. Strong sustainability initiatives include the integration of recycled EVA and participation in closed-loop material cycles, helping brands meet green supply chain goals.

Feltrax's focus is on ergonomic comfort and technical performance. The company's anti-fatigue insoles are anchored in proprietary EVA blends, offering improved energy return for work, walking, and athletic shoes. Their rapid prototyping service accelerates product development for brand customers, shortening time-to-market.

Lusoprene champions material innovation and environmental responsibility. They offer eco-EVA insoles made from renewable materials and biodegradable resins—popular among brands promoting eco-friendly footwear. Their advanced lamination and injection production lines accommodate uniquely shaped or multi-density insoles for niche and mainstream markets.

Polipis excels at anatomically shaped insoles that promote healthy posture and reduce fatigue, with a growing portfolio in medical and orthopedic applications. Automated molding and lamination ensure high production efficiency, while their EU-compliant quality assurance procedures guarantee consistent product performance. Polipis also supplies OEM insoles for safety and fashion sectors across much of Western Europe.

Beyond the major names, Portugal hosts a vibrant ecosystem of small and medium enterprises focused on niche EVA products, including antimicrobial insoles, children's orthopedic footbeds, and products integrating natural additives for increased comfort and performance. Brands benefit from the competition and diversity within Portugal's insole manufacturing community, ensuring access to a wide variety of technical and aesthetic options.

Portuguese manufacturers support both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) production. If you provide your own design specifications, top Eva Insole Manufacturers and Suppliers can deliver mass production with accurate branding, sizing, and packaging. Many factories have English- and French-speaking export managers to support smooth communication and address the specific needs of global buyers.

Typical OEM/ODM services include:

- Brand and logo imprinting

- Color and density modification

- Anti-slip or antibacterial surface customization

- Custom shape molds for anatomical or medical insoles

- Individualized retail or bulk packaging

This adaptability is invaluable for footwear startups, emerging brands, and large retail groups seeking to differentiate in crowded marketplaces.

Selecting the appropriate EVA formulation is crucial for comfort, durability, and end-customer satisfaction. Portuguese suppliers often offer technical guidance, helping brands determine the ideal blends for their footwear lines.

Production factories routinely test insoles for:

- Compression set and recovery

- Flexural fatigue

- Odor and moisture resistance

- Chemical and allergen safety

- Wear and abrasion resistance

Certified Eva Insole Manufacturers and Suppliers provide transparent documentation and batch tracking to assure buyers of consistent quality and regulatory compliance.

For larger-scale or cost-sensitive projects, many buyers partner with reputable Chinese EVA insole factories. China's manufacturing sector excels in automation, and its factories offer significant price advantages on large orders. Some Portuguese brands act as system integrators by designing in Portugal and producing at scale in China, then handling final quality checks and shipping from Europe. This blended sourcing approach lets brands take advantage of both European R&D and Asian production scale, without sacrificing quality or lead time.

Collaborations between Chinese and Portuguese EVA insole suppliers further drive innovation—shared knowledge brings new eco-materials and improved technical features to global footwear brands.

The market for EVA insoles is evolving quickly, driven by changing consumer demands and new manufacturing technologies.

- Use of recycled EVA foam derived from post-consumer shoes and factory waste

- Development of bio-based EVA using natural ingredients, such as sugarcane, to reduce fossil resource dependence

- Introduction of biodegradable packaging for shipped insoles

These innovations reflect growing demand for sustainability among both consumer brands and regulatory authorities worldwide.

Some leading Eva Insole Manufacturers and Suppliers in Portugal and China are developing “smart” insoles embedded with sensors that measure gait, step count, and even pressure distribution. This offers exciting opportunities for sports, healthcare, and activity tracking markets.

EVA insoles are rapidly gaining ground in the medical, elderly care, and children's footwear sectors, where specialized orthotic support is crucial. Customization in size, density, and shape enables better ergonomy and increased product value.

When selecting the right factory or supplier from Portugal, consider these factors:

- Production capacity: Is the supplier able to fulfill your order quantities, whether small trial runs or high-volume lines?

- Material expertise: Do they offer the precise EVA blends your footwear requires?

- Production lead time: Can they meet your launch schedule, especially during peak seasons?

- Certifications and compliance: Do they hold valid ISO, OEKO-TEX, or EU-specific certificates?

- Communication and after-sales service: Will you have a dedicated contact for updates and issue resolution?

- Flexibility in customization: Can the factory adapt molds, colors, and packaging to your latest market needs?

- Sustainability practices: Are their materials and processes environmentally responsible?

When necessary, request production samples, visit factories, or request third-party audits to confirm their qualifications.

Most Portuguese factories support efficient pre-sale consultation, prototyping, and transparent quotation so buyers can assess costs and timelines upfront. Western shipping ports such as Porto and Lisbon expedite deliveries to Europe, the Americas, and other global regions.

To ensure smooth transactions:

- Define your technical requirements clearly (material density, size, design, branding).

- Discuss packaging and shipping preferences in advance.

- Negotiate lead times and payment terms (many exporters accept letters of credit or secured T/T payments).

- Confirm after-sales support, including claims for faulty or delayed shipments.

Establishing a strong relationship with your Eva Insole Manufacturers and Suppliers will lead to long-lasting partnership benefits and reliable product pipelines.

Portugal holds a strategic position as one of Europe's top centers for Eva Insole Manufacturers and Suppliers. Its manufacturers deliver superior quality, advanced customization, and strong OEM/ODM support. From globally renowned component factories to innovative startups, Portuguese suppliers combine traditional skills with state-of-the-art automation, strict quality management, and eco-friendly practices to meet the evolving needs of international shoe brands.

Coupled with significant focus on green manufacturing and the integration of digital technologies, Portugal's EVA insole sector remains at the cutting edge of both performance and sustainability. Whether you are a footwear brand, a wholesaler, or a distributor seeking competitive edge, partnering with Portuguese EVA insole specialists provides an effective route to product excellence and market leadership.

EVA offers lightweight comfort, superior shock absorption, moisture resistance, and easy customizability, making it ideal for many types of footwear.

Yes, most leading Portuguese EVA insole suppliers offer full OEM and ODM capabilities, enabling clients to specify material density, colors, branding, shape, and packaging for unique product needs.

Ask for detailed product samples, technical datasheets, certifications, and laboratory test reports. Verified Eva Insole Manufacturers and Suppliers will be transparent and may offer third-party audits.

Yes, many factories in Portugal and China now offer eco-EVA options made from recycled materials or bio-based polymers to meet sustainability and regulatory requirements.

Production time ranges from several weeks for samples to 4-8 weeks for bulk orders, depending on order complexity and quantity. Shipping to Europe is very quick; deliveries to the US or Asia may require additional logistics planning.