Views: 222 Author: Edvo Publish Time: 2026-01-05 Origin: Site

Content Menu

● Understanding the Orthotic Insole Market in Canada

● Key Factors Driving Industry Growth

>> 1. Advanced Medical Collaboration

>> 2. Technological Innovation

>> 4. Rising Demand for OEM and Private Label Products

● Top Canadian Orthotic Insole Manufacturers And Suppliers

>> The Orthotic Group (Markham, Ontario)

>> Atlas Orthotic Lab (Calgary, Alberta)

>> SoleScience (London, Ontario)

>> Paris Orthotics Ltd. (Vancouver, BC)

>> Kintec Footwear + Orthotics (Surrey, BC)

● Expanding OEM and ODM Capabilities in Canada

● Collaboration Between Canadian and Chinese Manufacturers

● How to Choose the Right Orthotic Insole Supplier

● Trends and Future Outlook for Orthotic Insoles

● Why Canadian Manufacturers Are Trusted Worldwide

● FAQ

>> 1. What makes Canadian orthotic insole suppliers different from others?

>> 2. Do Canadian manufacturers offer private-label production?

>> 3. Are Canadian insoles suitable for both sports and medical use?

>> 4. How can overseas companies source from Canada efficiently?

>> 5. Is it possible to combine Canadian design with Chinese mass production?

Canada has emerged as a strategic hub for Orthotic Insole Manufacturers And Suppliers, bringing together medical expertise, material science, and innovative design. As foot health awareness spreads globally, Canadian manufacturers are attracting increasing attention from brands, wholesalers, and distributors seeking high-quality orthotic products. Whether designed for professional athletes, medical patients, or everyday comfort, orthotic insoles from Canada represent a strong balance of functionality, sustainability, and innovation.

The Canadian orthotics sector has evolved far beyond traditional podiatry clinics. It now encompasses sports technology, lifestyle comfort wear, and medical rehabilitation. Over the past decade, demand has risen exponentially due to lifestyle changes, aging populations, and increasing health awareness. Daily wearers seek improved posture, reduced fatigue, and prevention of foot injuries, all of which have strengthened the domestic and export markets for orthotic insoles.

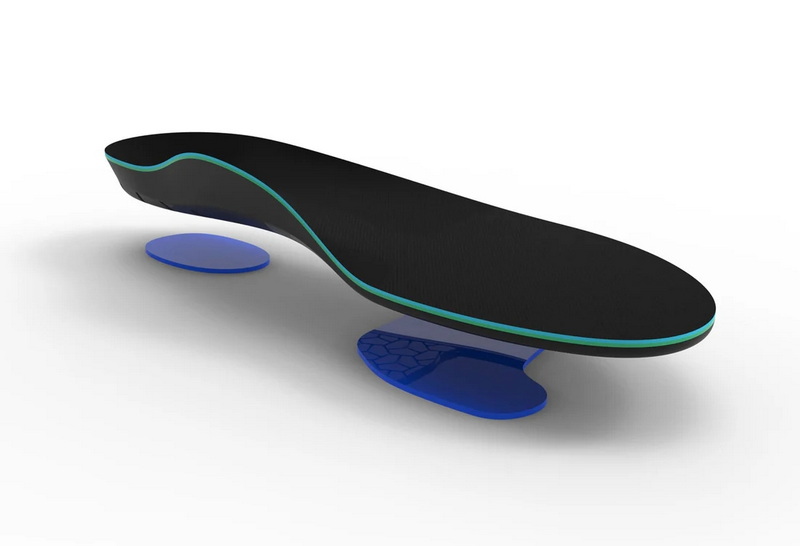

Canadian Orthotic Insole Manufacturers And Suppliers combine advanced biomechanics with modern materials such as EVA foam, PU gel, and carbon fiber to create lightweight yet durable products. Their ability to balance comfort with corrective support has made them valuable partners for international footwear brands, health institutions, and orthotic clinics.

Another key aspect of Canada's industry is ethical and sustainable sourcing. Many companies use recyclable materials or focus on eco-friendly alternatives like cork, bamboo, or plant-based polymers. This commitment not only aligns with global environmental goals but also attracts conscious consumers and importers.

Canada's orthotic insole industry continues to grow because of several unique factors:

Manufacturers work closely with podiatrists, physiotherapists, and sports medicine experts to design products backed by clinical data. These collaborations ensure every insole supports optimal alignment and reduces strain on knees and hips.

Digital scanning, 3D printing, and computer-aided design have transformed how insoles are produced. These technologies enable highly precise customization, accommodating individual gait patterns and arch structures.

With North America's strong logistics networks, Canadian Orthotic Insole Manufacturers And Suppliers easily export to the U.S. and international markets. Their products meet global quality certifications, ensuring reliability and easy compliance for importers.

Many overseas brands now rely on Canadian companies to produce custom-branded orthotic insoles under OEM contracts. This model allows companies to maintain brand identity while accessing high-quality manufacturing without large infrastructure investments.

Below is a detailed overview of leading companies recognized for their product innovation, manufacturing integrity, and strong export partnerships.

Sole is one of the most recognizable brands in the orthotic insole market. The company's moldable insoles offer personalized fit and cater to both performance athletes and casual users. Their materials are sustainable, using recycled cork compounds and environmentally conscious packaging. Sole's products are distributed globally, and the company provides OEM services for international partners seeking green production and comfort technology.

This firm specializes in customized medical-grade orthotics designed using advanced gait analysis systems. The Orthotic Group serves healthcare professionals, offering precise solutions for diverse foot conditions like plantar fasciitis and flat feet. Their facilities are equipped with high-accuracy CNC milling tools, allowing consistent and repeatable quality. The company's strong clinical background makes it a trusted name in healthcare-driven orthotics.

Atlas Orthotic Lab stands out for combining science and sports. Known for creating performance-driven orthotics for athletes, it integrates motion analysis and biomechanical assessment into product development. The lab's manufacturing process ensures each insole enhances movement efficiency while minimizing injury risk. Atlas also accepts OEM orders from global sportswear brands aiming to incorporate specialized orthotics into footwear lines.

SoleScience operates at the intersection of research and production. The company is renowned for integrating medical engineering into its design workflow. Their orthotic solutions are evidence-based and highly durable, making them popular in hospital systems and clinical networks. SoleScience frequently collaborates with international distributors, offering customized adaptations for different regional needs and preferences.

Paris Orthotics combines decades of experience with technological efficiency. Its digital platform allows clinics to submit patient scans remotely, while the manufacturing center produces fully customized orthotics using advanced thermoplastic compounds. This seamless system makes the company a preferred partner for health professionals and footwear firms requiring medical customization at scale. Their OEM capabilities empower foreign brands to expand product lines without maintaining in-house facilities.

Kintec is both a retailer and a manufacturer, bridging professional orthotic services with consumer convenience. Their clinics collect foot data using advanced scanning tools, while the production division manufactures insoles based on these profiles. Kintec's approach merges precision and accessibility, ensuring clients—from athletes to casual users—receive optimal comfort solutions. The company also offers private-label services for sports and comfort footwear brands.

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services have become crucial within the orthotic insole industry. Canadian suppliers don't just produce—they innovate. For international buyers, this reduces R&D costs while accelerating market entry.

Key benefits include:

- Custom engineering: Brands can adapt design specifications, materials, and patterns to meet target demographics.

- Scalable production: Medium- to large-scale batches can be produced efficiently while maintaining strict quality standards.

- Brand alignment: Logos, color schemes, and retail packaging are incorporated seamlessly for cohesive branding.

- Medical-grade validation: Products are tested following biomedical protocols to meet international health standards.

Such manufacturing flexibility has strengthened Canada's position as a global leader in orthotic production.

To balance cost and innovation, many Canadian Orthotic Insole Manufacturers And Suppliers collaborate with experienced Chinese partners. China's large-scale manufacturing infrastructure complements Canada's advanced design and medical research capabilities. Together, they create a global production pipeline that blends expertise and efficiency.

As one of China's leading insole factories, our company partners with global brands—including Canadian orthotic developers—to deliver affordable, durable, and medically aligned insoles. We specialize in material optimization (EVA, PU, carbon fiber, and gel), precision molding, and full-brand packaging solutions. Through OEM collaborations, we help international partners scale their business while ensuring consistent product quality.

This cross-border model allows both Canadian and Chinese manufacturers to meet the rising global demand for high-quality insoles while maintaining competitive price points and diverse customization options.

Selecting an ideal insole supplier requires evaluating several key criteria. Whether sourcing from Canada or through international OEM networks, companies should focus on these elements:

1. Product specialization: Determine whether the supplier focuses on medical, sport, or comfort insoles. Specialized manufacturers usually deliver better performance.

2. Material innovation: Look for suppliers utilizing the latest foam composites, breathable fabrics, or antimicrobial coatings.

3. Design technology: 3D scanning accuracy and digital modeling directly impact product quality and customization precision.

4. Production facilities: Inspect capacity, hygiene standards, and quality management systems before establishing long-term contracts.

5. Communication and flexibility: Choose suppliers with experience handling international logistics, documentation, and certification.

Strategic partnerships with suppliers that integrate both innovation and efficiency guarantee long-term brand competitiveness.

The orthotic insole industry continues to evolve rapidly. In Canada, several innovations are reshaping the future:

- Smart orthotics: New insoles feature integrated sensors to monitor posture and balance, helping users improve movement efficiency.

- 3D-printed custom insoles: Automation allows clinics and brands to produce made-to-order insoles quickly and affordably.

- Biodegradable options: Manufacturers are reducing plastic dependency by introducing sustainable foams and organic materials.

- Hybrid comfort systems: Combining soft cushioning layers with rigid stabilizers creates insoles suitable for both health and performance uses.

- Cloud-based customization: Clinics and retailers can now transmit gait data digitally to manufacturing labs for faster turnaround.

As Canadian and global buyers increasingly prioritize comfort, sustainability, and health-driven product design, orthotic insole manufacturers who invest in these innovations will lead the market for years to come.

Canadian Orthotic Insole Manufacturers And Suppliers are respected for several reasons beyond product quality. Their consistent service ethics and reliability make them preferred partners for distributors and wholesalers abroad. The industry's regulatory system ensures compliance with medical-grade standards and consumer protection guidelines. Moreover, Canadian manufacturers emphasize transparency in sourcing, fair labor, and environmental sustainability—values that align with the global market's growing expectations.

For international buyers seeking balanced partnerships, Canada offers the rare combination of technological depth, ethical production, and personalized service. These strengths, coupled with global partnerships—particularly with Chinese OEM networks—create unparalleled opportunities for expanding across diverse markets including health retail, sportswear, and comfort footwear.

Canada stands as one of the most reputable centers for Orthotic Insole Manufacturers And Suppliers, offering a blend of clinical precision, material innovation, and sustainable production values. Its companies are redefining footcare manufacturing by combining medical expertise with modern technology, supported by solid OEM and global export capabilities.

For foreign footwear brands, wholesalers, and private-label businesses, partnering with Canadian manufacturers delivers strategic benefits: dependable quality, flexible customization, and market-ready technology. When combined with Chinese large-scale production advantages, this partnership model forms a complete ecosystem that serves both healthcare and lifestyle markets effectively.

As the orthotic insole industry continues to expand, companies that embrace cross-border collaboration will be best positioned to meet future demands for comfort, health, and sustainability in global footwear design.

Canadian suppliers blend clinical expertise with technology. Their products are often designed in collaboration with medical professionals, ensuring precision in posture correction and long-term comfort.

Yes. Most Orthotic Insole Manufacturers And Suppliers in Canada provide OEM and private-label services, allowing international brands to design customized orthotics with branded packaging.

Absolutely. Many manufacturers produce dual-function insoles that combine medical-grade support with athletic performance, suitable for running, hiking, or daily wear.

International buyers can contact suppliers directly through export teams or collaborate via established OEM networks. These suppliers handle design communication, certification, and shipping logistics efficiently.

Yes. Many brands use Canadian orthotic designs and partner with Chinese factories for large-scale production, ensuring quality design integration with cost-effective manufacturing.