Views: 222 Author: Edvo Publish Time: 2026-01-06 Origin: Site

Content Menu

● Why Consider Replacing Insoles?

● Signs That It's Time to Replace Your Insoles

● Choosing the Right Insoles for Old Shoes

>> 3. Shoe Type

● How to Replace Insoles in Old Shoes

● Benefits of Putting New Insoles in Old Shoes

>> 1. Revived Comfort and Cushioning

>> 3. Odor and Hygiene Control

● Common Mistakes When Replacing Insoles

● Additional Tips for Maintaining Insoles

● Can You Use the Same Insoles for Different Shoes?

● The Role of Insoles in Foot Health

● How Long Do Replacement Insoles Last?

● How to Choose OEM Insoles for Your Brand

● Why OEM Insoles Are a Smart Business Choice

● Custom Types of Insoles Manufactured Today

● The Environmental Value of Replacing Insoles

● FAQs

>> 1. How often should I replace my insoles?

>> 3. Are all replacement insoles universal?

>> 4. Can new insoles fix poorly fitting shoes?

>> 5. What materials are best for hot climates?

When your favorite shoes begin to feel uncomfortable, it's easy to assume they've reached the end of their life. But in many cases, it's not the shoes themselves that are worn out—it's the insoles inside them. Whether you're dealing with flattened cushioning, unwanted odor, or sore feet, replacing your old shoe insoles could be a simple and effective solution.

So, can you put new insoles in old shoes? Absolutely. Doing it properly not only revives comfort and fit but can also extend the life of your shoes. In this article, we'll explore the benefits of replacing old insoles, how to choose the right ones, and what to expect from professional OEM insole manufacturing.

Many people underestimate the importance of insoles. They act as the foundation for your feet, absorbing shock, maintaining balance, and supporting your natural arch. Over time, daily wear breaks down the material, leading to loss of comfort and support. Replacing them offers several important benefits:

- Restored comfort: Fresh insoles cushion your feet again, reducing stress on joints.

- Improved support: Customized or ergonomic insoles help maintain proper posture.

- Hygiene enhancement: Old insoles trap moisture, sweat, and bacteria; replacements bring cleanliness.

- Extended shoe life: Fresh insoles reduce wear inside the shoe, delaying the need for full replacement.

- Reduced fatigue: When insoles perform correctly, you expend less energy walking or standing.

For workers, athletes, or frequent travelers, this simple improvement can make a world of difference.

It's not always visually obvious that an insole has worn out. Your shoes might still look fine on the outside while the internal support has degraded. Here are the most common warning signs:

- Flattened cushioning: Your heels or arches feel closer to the ground than before.

- Lingering odor: Persistent smells despite cleaning suggest bacterial buildup.

- Visible damage: Torn fabric, cracks, or compressed areas signal material fatigue.

- Soreness or pain: Recurring heel, knee, or lower back pain can indicate lost support.

- Loose movement: If insoles shift when walking, they no longer fit the shoe properly.

In most cases, replacing insoles every 6–12 months keeps your footwear in top condition.

Selecting the best replacement insole for your shoes depends on multiple factors including your activity type, foot structure, and comfort preferences. Here are the key considerations.

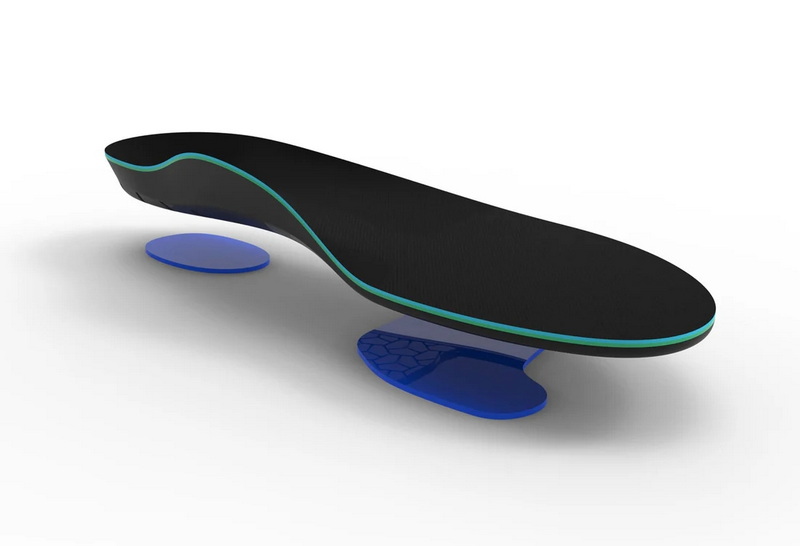

Insoles are made from various materials, each serving a different purpose:

- EVA Foam: Lightweight and flexible, suitable for athletic or casual use.

- Gel: Great for shock absorption and comfort during high-impact movement.

- Leather: Ideal for dress shoes, providing firmness and breathability.

- Cork: Offers natural odor control and firm arch support.

- Memory Foam: Molds to your foot shape for a customized fit.

Understanding material behavior helps you match the right texture and density to your shoe type.

Every person's arches differ in height and shape. The wrong insole can stress the feet instead of supporting them.

- Flat Feet: Choose insoles offering firm medial support.

- Normal Arch: Use moderate cushioning that retains flexibility.

- High Arch: Pick thicker, contoured insoles that disperse pressure across the heel and forefoot.

The same insole design won't work for all shoes. Runners need lightweight, breathable foam; hikers require thicker models with moisture management; and professionals often prefer thin leather or memory foam for discreet comfort.

Most insoles are “trim-to-fit,” meaning you can cut them to follow your shoe size. Always use your old insole as a model for trimming accuracy.

Advanced insoles now include moisture-wicking layers, antibacterial coatings, and temperature regulation fabrics. These designs help maintain comfort even during intensive daily use.

Proper installation ensures your new insoles deliver the intended results. Follow these steps:

1. Remove the existing insole. Carefully lift from the heel to the toe, avoiding tearing.

2. Clean the shoe interior. Wipe using a soft damp cloth and air dry to remove dirt or residue.

3. Trim the new insole if needed. Place old and new insoles together and cut following the outline.

4. Fit and test. Insert the insole flatly and ensure there's no curl at the edges. Walk around to confirm balance.

5. Adjust if necessary. Minor trimming or repositioning might be needed for perfect alignment.

Replacing insoles is quick and simple—it usually takes less than ten minutes per pair.

Reinserting new insoles does more than improve comfort; it revitalizes the entire footwear experience.

After months of compression, old insoles lose their structure. Fresh insoles restore impact resistance, preventing soreness and allowing energy-efficient walking.

By renewing interior support, you delay outer sole wear and extend the usefulness of your shoes by many months.

New insoles often come with odor-resistant materials or antimicrobial coatings that combat sweat and bacteria, keeping old shoes fresh.

Instead of buying a new pair of shoes, you can achieve similar comfort for a fraction of the price.

Shoe production consumes materials and energy. By reusing existing footwear with new insoles, you reduce waste and contribute to sustainability.

If you walk or work long hours, supportive insoles improve posture and foot alignment, reducing fatigue and muscle strain.

Avoid these common errors that can limit your results:

- Layering new over old insoles. This makes shoes too tight and reduces airflow.

- Selecting the wrong size. Oversized insoles cause slippage; undersized ones slide or leave gaps.

- Ignoring shoe condition. Insoles can't repair cracked soles or deformed outsoles.

- Skipping cleaning. Dirty interiors trap bacteria under new insoles.

- Neglecting arch matching. Using an incorrect shape can increase foot strain instead of reducing it.

Taking time to measure and clean properly ensures maximum improvement.

Small habits can extend the lifespan of your insoles dramatically:

- Rotate pairs. Alternate between shoes daily to allow proper ventilation.

- Keep dry. Remove insoles after wearing and let them air out.

- Wash occasionally. Foam or fabric types should be hand-washed with mild soap and water.

- Refresh leather insoles. Clean gently with a damp cloth and use conditioner if necessary.

- Replace liners regularly. If you walk or run heavily each day, refresh every few months.

These preventive actions preserve freshness and function even in older footwear.

Yes, transferable insoles are common, especially for pairs of similar size and design. However, you should avoid constant switching between shoes of very different shapes—like running shoes and dress shoes—because each model fits the foot differently. Dedicated insoles for separate shoe types often provide better performance and hygiene.

Insoles are more than soft padding—they influence your overall body alignment. Poor insoles can affect gait and pressure distribution, leading to aches in the knees, hips, or back. For example:

- Overpronation (rolling inwards): Corrective insoles balance ankle movement and prevent fatigue.

- Flat Feet: Custom orthotic insoles help maintain natural arches and protect from plantar pain.

- High Arches: Special cushioning dissipates pressure across heel and forefoot to avoid tension.

By replacing insoles before complete breakdown, you maintain proper posture and prevent long-term discomfort.

Durability depends on material composition, weight, and daily use. Foam or gel-based insoles typically survive six to ten months of active wear, while high-end orthotic or leather options can last over a year. If you feel reduced cushioning or see deformation, it's time for replacement. A simple visual and comfort test once per season ensures consistent support.

For businesses, custom-designed insoles are a strong branding opportunity. Manufacturers offering OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services allow brands to build a unique product identity through tailored materials, packaging, and finishing. Key selection factors include:

- Raw material quality control. High-density EVA and PU foam ensure consistent performance.

- Design flexibility. Options for thickness, texture, and color help differentiate the brand.

- Mass production capability. Ensure scalable capacity and delivery reliability.

- Brand customization. Private labeling, logos, or packaging to align with market positioning.

- Sustainability consideration. Eco-friendly EVA and recycled materials attract modern consumers.

Cooperating with a leading Chinese insole manufacturer ensures efficient production, competitive costs, and expert technical guidance throughout design and shipment.

If your company produces or sells footwear, offering proprietary insoles helps strengthen customer retention. Branded OEM insoles not only improve foot comfort but also increase product value. Incorporating professionally produced insoles allows brands to:

- Offer consistent quality control.

- Differentiate products within competitive markets.

- Adapt quickly to seasonal or performance trends.

- Complement full-shoe product lines with accessories.

China's manufacturing ecosystem provides access to advanced molding, automation, and diverse material expertise, making OEM insoles both reliable and scalable for global supply chains.

Modern insole manufacturing includes a vast variety of specialized designs:

- Sports performance insoles – engineered for running, basketball, or hiking with added flexibility and shock resistance.

- Orthopedic corrective insoles – customized support for medical or posture correction.

- Work and safety shoe insoles – built with sturdy anti-fatigue materials for industrial use.

- Eco-friendly insoles – using recycled EVA, bamboo charcoal, or biodegradable foam.

- Fashion and lifestyle insoles – thin, stylish layers compatible with formal shoes.

Advanced OEM facilities can also produce mixed-type insoles combining multiple materials for dual comfort and durability.

Each year, millions of used shoes are thrown away while their outer materials remain intact. Renewing insoles instead of discarding shoes dramatically reduces environmental impact. It limits waste, conserves material resources, and encourages a circular product lifecycle.

Many manufacturers now use recyclable or biodegradable polymers to create insoles that combine performance with sustainability. Small steps like replacement rather than disposal embody responsible consumer behavior that benefits both comfort and the planet.

Replacing insoles in old shoes is one of the simplest yet most effective ways to rejuvenate comfort and functionality without buying new footwear. New insoles restore cushioning, maintain correct posture, and improve hygiene, all while extending the shoe's usability.

For individuals, it means comfort and savings. For brands and wholesalers, it represents an opportunity to offer value-added, customizable products through reliable OEM suppliers. Whether you choose cushioned sports inserts, leather formal insoles, or eco-friendly EVA foam designs, the principle is the same—fresh insoles can give old shoes a second life.

Treat your footwear as a long-term investment: proper maintenance, timely insole replacement, and smart material choices keep your feet supported and your steps comfortable for miles to come.

For most shoes, a replacement every 6 to 12 months offers optimal comfort and hygiene. Heavy users or athletes may need to change them more frequently.

Yes. Hand-wash with mild soap and air-dry completely. Avoid machine drying, as heat can deform foam or gel components.

Not entirely. While many come as trim-to-fit, differences in shoe shape, size, and arch profile mean customization ensures the best performance.

They can improve comfort but cannot correct shoes that are too tight or structurally damaged. Fit must still align with shoe sizing.

Breathable and moisture-wicking materials like open-cell foam, natural cork, or mesh fabric are excellent for keeping feet cool and dry.