Views: 222 Author: Edvo Publish Time: 2025-11-07 Origin: Site

Content Menu

● Understanding Heat Moldable Insoles

>> Advantages of Heat Moldable Insoles

● Step-by-Step Guide: Molding Heat Moldable Insoles at Home

>> Step 1: Prepare Your Workspace

>> Step 2: Fit and Trim the Insoles

>> Step 3: Preheat Your Heating Appliance

>> Step 5: Insert and Mold the Insoles

>> Step 6: Allow to Set and Cool

>> Step 7: Final Fit and Usage

● Best Practices and Professional Tips

● Manufacturing Insights: How Are Heat Moldable Insoles Made?

>> Manufacturing Process Steps

● Technical Innovations and Trends

● Troubleshooting Your Custom Fit

● Care, Cleaning, and Longevity

● Product Selection: Choosing the Right Heat Moldable Insoles

● FAQs

>> 1. Can I remold my heat moldable insoles if I make a mistake?

>> 2. What types of shoes are compatible with heat moldable insoles?

>> 3. Is it safe to use a microwave to heat insoles?

>> 4. How often should I replace or remold heat moldable insoles?

>> 5. Are these insoles suitable for people with special foot conditions?

Heat moldable insoles have revolutionized the comfort and customization of footwear, offering a personalized fit for diverse users, from athletes to people seeking extra support in everyday shoes. Beyond simple comfort, the process and technology behind heat moldable insoles reflect advances in materials science, manufacturing, and user accessibility.

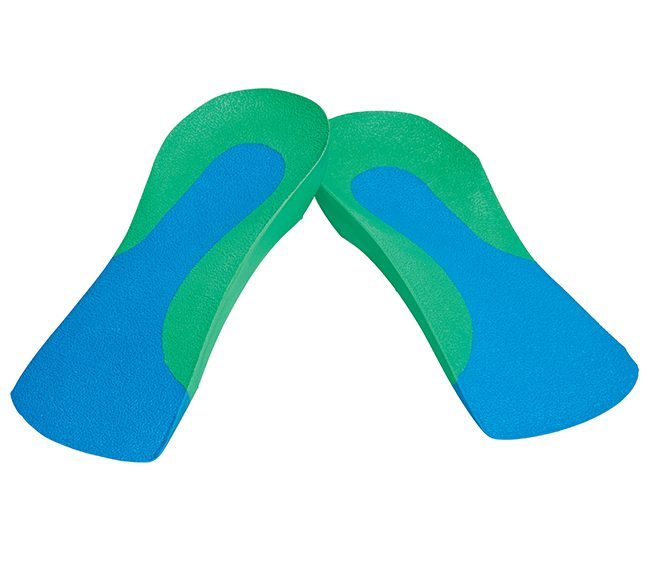

Heat moldable insoles are advanced footbeds engineered from thermoplastic polymers, EVA, or specialized foams that become flexible at certain temperatures. Once heated, these inserts can be shaped exactly to the user's foot, creating a secure, comfortable, and biomechanically correct foundation for movement. This superior fit can alleviate pain, prevent foot ailments, and increase overall foot health.

- Personalized fit: Each insole molds to the pinpoint details of your sole, ensuring comfort.

- Enhanced support: Custom arch support reduces fatigue during prolonged use.

- Versatility: Suitable for everything from running shoes to hiking boots, work boots, and medical footwear.

- Reduced break-in time: Achieve comfort and support right from the first wear.

- Better performance: Proper alignment and foot stabilization translate to improved athletic output and injury prevention.

Getting a perfect fit with heat moldable insoles is possible in the comfort of your own home with just a few tools and some attention to detail. The process is straightforward, but following each step ensures optimal results.

Set up a clean, heat-safe area with the following items at hand:

- Pair of heat moldable insoles

- The shoes you plan to use

- Scissors for trimming (if needed)

- Conventional or toaster oven, or a specialized heat gun

- Timer

- Socks (to protect your feet during pressing)

- Heat protection gloves (optional but recommended)

Before heating, insert the insoles into your shoes to check fit. If the insoles extend beyond the original insole, use the old insole as a template to trim the new ones for a perfect match. Ensure the insole fits snugly along the shoe walls without folding or bunching.

Most conventional ovens should be set to 200°F (93°C) to 225°F (107°C). Avoid microwaves, as they deliver uneven heat and may damage thermoplastics.

If you have a heat gun, set it to its lowest effective setting for gradual, controlled heating.

- Place one insole (fabric side up) on a baking tray and insert it into the oven.

- Most insole brands recommend heating for 90–120 seconds or until you notice a color-changing tab or the material becomes noticeably softer.

- Always heat ONE insole at a time to ensure proper attention and minimize the risk of overheating.

Quickly place the heated insole into your shoe and, wearing socks, stand up inside the shoe. Lace or fasten the shoe securely. Stand with feet shoulder-width apart, applying even pressure for 2 minutes. Avoid fidgeting or shifting to maintain a smooth, neutral imprint.

After molding, remove your foot and let the insole cool while remaining inside the shoe. This step is essential for the material to retain its new form. The process can be repeated for the second insole.

After both insoles are fully cooled, ensure they are comfortably seated in your shoes. Your now-customized insoles are ready for daily wear, providing you with stability, personalized support, and maximum comfort.

- Always use socks during molding sessions for skin safety.

- Never microwave insoles; stick to oven or heat gun methods.

- If unsure, consult the manufacturer for temperature/time specifics.

- If the fit feels incorrect after setting, most insoles can be reheated and corrected several times.

- For high arches or medical needs, consider standing on a soft rubber pad during molding for enhanced arch profiling.

- Overheating the insole can warp or degrade the material permanently.

- Uneven standing or unbalanced pressure will yield an inaccurate mold.

- Skipping the trimming step if your shoes are narrow or pointed.

To understand the science behind heat moldable insoles, it's helpful to look at their production process, which combines advanced materials with modern molding technology.

Most heat moldable insoles are created from:

- Thermoplastic polymers: These soften at 60–80°C, and can be molded repeatedly.

- EVA (ethylene vinyl acetate): Known for excellent cushioning and moldability.

- PU (polyurethane): Offers both durability and comfort.

These materials are chosen for their low activation temperatures, flexibility, resilience, and safety, making them perfect for repeated, at-home customization.

1. Material Preparation: Thermoplastic sheets or foams are cut to rough insole shapes. This can involve die cutting or advanced CNC trimming for precision.

2. Heating: The material is uniformly preheated using industrial ovens or infrared heaters.

3. Forming: Once pliable, the materials are either vacuum formed over a foot-shaped mold or pressed inside a heated metal cast, sometimes with the use of foot models to replicate the user's footprint.

4. Multi-Layer Construction (Optional): Some insoles incorporate a soft midsole, rigid support shell, or specialty top layer to offer more features.

5. Trimming and Finishing: The insole is trimmed, edge-finished, and surface treated for comfort, durability, and breathability.

6. Quality Control: Dimensions, flexibility, and moldability are tested to ensure consistent performance standards.

For fully custom insoles (such as for medical use), the process may also include:

- Scanning or casting of the user's foot.

- CAD design of the orthotic.

- Multi-material layering, including resin-reinforced fiber or silicone injection for bespoke support zones.

- Final finishing, covering, and inspection.

Modern heat moldable insole design embraces several innovations:

- Integrated antimicrobial coatings for odor resistance.

- Moisture-wicking top covers for foot health.

- Shock-dispersing gel pads embedded at high-impact zones.

- Color indicators that signal when the insole is ready to mold.

- Environmentally-friendly plant-based or recyclable materials.

- Modular inserts to target specific support needs.

These features have increased demand from high-performance athletes, outdoor sports enthusiasts, and individuals needing professional-grade orthotics.

Heat moldable insoles serve a wide range of user groups:

- Athletes: Enhanced support translates to better biomechanics and fewer injuries.

- Outdoor professionals: Long-lasting support for those on their feet all day.

- Diabetics or medical users: Reduce pressure points and risk of ulcers.

- Seniors: Custom fit improves stability and reduces fall risk.

- Children: Accommodates growth with adjustable fit.

Additionally, OEM manufacturers offer bulk and contract production for global brands, building private label products with specific features, shapes, and levels of customization to meet market demands.

If your first attempt does not yield a perfect result, don't worry. Most heat moldable insoles offer several opportunities to remold. If the support feels uneven, simply repeat the heating process and press for another perfect impression.

Modern insoles are rated for multiple remoldings and daily durability. Should you notice persistent discomfort or lack of support even after several attempts, consult with a professional fitter or podiatrist, especially if you have specific foot conditions.

- Remove your insoles regularly for airing out to prevent moisture buildup.

- Hand wash only with mild soap and water, and let them air-dry (never use direct heat).

- Replace insoles annually or when the arch support or cushioning becomes noticeably compressed.

Regular care increases insole longevity and ensures consistent comfort and support over time.

When selecting insoles, consider:

- Material type (EVA, PU, thermoplastic).

- Shoe compatibility (athletic, work, hiking, casual).

- Thickness and arch profile.

- Durability and ability to remold.

- Value-added features (antimicrobial, moisture wicking, gel inserts).

Test fit insoles in your intended footwear before molding for best results.

Heat moldable insoles are an accessible, high-impact solution for anyone seeking custom comfort, injury prevention, and optimal foot support. By combining smart materials, thoughtful engineering, and simple home-molding processes, these insoles have set a new standard in adaptable footwear. Whether you're a brand, a wholesaler, or an individual, customizing fit and function is now within your reach—making healthier, happier steps a reality for everyone.

Yes, most products allow multiple reheats and re-moldings for optimal fit.

Suitable for various closed-toe shoes—athletic, work, boots, and casual footwear.

Do not use microwaves; opt for ovens or heat guns for safe, even heating.

Replace annually or when they lose support; remold anytime the fit feels off.

Absolutely, with guidance from a podiatrist for specific medical or orthopedic needs.