Views: 222 Author: Edvo Publish Time: 2026-02-11 Origin: Site

Content Menu

● Overview of the Performance Insoles Industry in France

● Key Strengths of French Performance Insoles Manufacturers

>> Advanced Materials and Biomechanical Design

>> Quality and Certification Standards

>> Eco-Friendly Production Initiatives

● Leading Performance Insoles Manufacturers And Suppliers in France

>> Sidas Group

>> Adaptafoot

>> Confort Orthopédique France

>> Noene France

● OEM and ODM Cooperation Opportunities

● Supply Chain Integration and Global Collaboration

● Market Trends Reshaping the Industry

● Why Choose French Performance Insoles Manufacturers

● Future Prospects of the Performance Insoles Industry

● FAQs About Performance Insoles Manufacturers And Suppliers in France

>> 1. What distinguishes French performance insoles from others?

>> 2. Do French manufacturers customize designs for brands?

>> 3. Are French insoles environmentally friendly?

>> 4. How can I verify supplier credibility?

>> 5. Can French and Chinese manufacturers cooperate effectively?

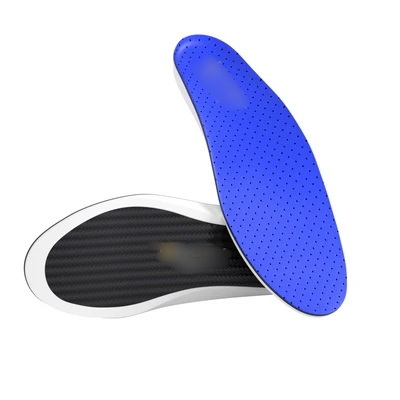

Performance insoles have become a key segment of modern footwear innovation. Designed to optimize comfort, stability, and energy efficiency, they serve athletes, workers, and everyday users alike. Across the global footwear supply chain, Performance Insoles Manufacturers And Suppliers in France are gaining significant attention for their advanced engineering, sustainable materials, and precise OEM capabilities.

For brands, distributors, and medical organizations worldwide, France offers a unique blend of craftsmanship, scientific expertise, and adaptive manufacturing—making it a premium destination for sourcing professional-grade insoles.

Over the past decade, France has emerged as a pivotal hub for performance footwear innovation. The country's manufacturers combine traditional European craftsmanship with state-of-the-art engineering and research-based development. As a result, Performance Insoles Manufacturers And Suppliers in France are now recognized for their capability to meet the evolving needs of global brands.

Several prominent factors drive the market's growth:

- Rising public awareness of foot health and ergonomic posture.

- Increasing participation in sports such as running, cycling, skiing, and hiking.

- Expansion of medical orthotic applications for postural correction.

- Technological integration of smart and bio-mechanical materials.

The competitive advantage of French insole producers lies in their combination of creativity and science. Every prototype is built not just for comfort, but to enhance superior performance for end-users across diverse lifestyles.

French manufacturers lead in developing sophisticated materials such as EVA foam, PU gel, TPU reinforcements, and carbon fiber inserts. These materials are precisely layered to balance shock absorption, flexibility, and breathability. Many factories embed antibacterial coatings and micro-ventilation channels to ensure hygiene and moisture control.

Additionally, French R&D engineers employ biomechanical modeling to evaluate foot pressure distribution, gait motion, and balance. This scientific approach allows Performance Insoles Manufacturers And Suppliers to craft products that maximize energy return and minimize fatigue during extended use.

One of the strongest appeals for international buyers lies in the OEM/ODM capabilities of French manufacturers. Whether you're a sports brand, orthopedic distributor, or fashion footwear designer, these suppliers provide:

- Customized size, shape, and density.

- Personalized color schemes and surface textures.

- Logo embossing and branded packaging options.

- Flexible MOQ (minimum order quantity) for prototype testing.

Such sophisticated OEM processes make France a preferred location for brands looking to launch new product lines without building their own manufacturing facilities.

French manufacturers strictly follow European Union standards for health, safety, and sustainability. Most companies hold certifications like ISO 9001, CE Marking, and REACH compliance—ensuring quality consistency and environmentally friendly production. This emphasis on certified quality gives global buyers full confidence when importing French-made insoles.

Sustainability has become integral to modern insole manufacturing. Many leading Performance Insoles Manufacturers And Suppliers now incorporate plant-based foams, recycled EVA, and water-based adhesives. Some have even introduced bio-degradable packaging materials, minimizing the carbon footprint across the product life cycle. This eco-friendly approach not only supports global green goals but also enhances the brand value of French manufacturers on the international stage.

Founded in 1975, Sidas Group is one of Europe's pioneers in custom-fit insole solutions. Its products combine medical precision with sports performance—trusted by Olympic athletes and major footwear labels alike. The company utilizes thermoforming and 3D scanning to create ergonomically accurate insoles tailored to every foot type.

Key features:

- Strong OEM collaboration with global sports brands.

- Specialization in running, skiing, cycling, and medical insoles.

- International distribution in more than 50 countries.

- Use of proprietary materials for enhanced energy response.

Adaptafoot integrates French design with medical-grade innovation. Their biomechanical engineers develop multi-density insoles that promote correct alignment while offering excellent cushioning. The company caters to both retail and industrial orders, including orthopedic clinics and e-commerce platforms.

Why they stand out:

- State-of-the-art CAD modeling and custom fit simulation.

- Dedicated OEM division for bulk private-label production.

- Focus on both performance and therapeutic applications.

With expertise spanning decades, Confort Orthopédique France specializes in anatomically shaped insoles providing foot correction, comfort, and motion control. Their insoles are widely used in medical institutions and fitness retail channels.

Highlights:

- Extensive portfolio: diabetic insoles, arch supports, and occupational protective insoles.

- Integration of natural cork and high-density foam materials.

- Proven track record in long-term OEM partnership projects.

Noene France has earned a global reputation for its cutting-edge vibration-absorbing technology. The company's patented elastomer-based material disperses shock waves generated by repetitive impact, protecting joints and ligaments. This makes their insoles especially popular among marathoners and high-impact athletes.

Key benefits:

- Ultra-thin design with exceptional shock-dissipation properties.

- Tested and certified under European sports research programs.

- OEM production for performance footwear brands worldwide.

Epitact Sport combines medical science and athletic innovation. Known for its silicone and gel-based technologies, the brand focuses on injury prevention, comfort enhancement, and postural support. Their insoles provide anti-friction zones and are sold in over 40 countries.

Advantages:

- Patented silicone-gel protection system.

- Continuous research in podiatry and biomechanics.

- Private-label production for sports gear retailers.

Performance Insoles Manufacturers And Suppliers in France welcome OEM cooperation with international partners seeking premium, certified products. These collaborations follow structured project development stages:

1. Concept & Design Brief: Clients specify product goals, functions, and target users.

2. Material Selection: Engineers recommend suitable materials for durability, flexibility, and sustainability.

3. Prototype & Testing: Rapid 3D printing or sample molding ensures functional testing before mass production.

4. Mass Production: Automated cutting, stitching, and lamination machines deliver consistent quality.

5. Quality Assurance: Each batch undergoes visual, mechanical, and wear-performance inspections.

6. Packaging & Shipping: Products can be labeled, branded, and packed according to clients' preferences.

Such well-structured systems help global buyers streamline their supply chains and minimize risks associated with overseas manufacturing.

French manufacturers often collaborate with European designers and Asian mass-production facilities to balance cost efficiency and innovation. A typical model involves prototype design and quality control in France, followed by large-scale manufacturing in partner factories in China or Vietnam.

For instance, a French sportswear brand may design a high-performance insole line domestically, conduct testing and certification in Europe, and work with a Chinese OEM partner for scalable production. This hybrid strategy ensures quality assurance while maintaining global cost competitiveness.

This cross-border partnership approach has become a hallmark of modern Performance Insoles Manufacturers And Suppliers, allowing them to reach wider markets without compromising quality.

The insole industry continues to evolve rapidly under the influence of new technologies and consumer demands. Several critical trends define the modern market landscape:

- Personalized Fit through 3D Printing: Custom insoles generated from user foot scans, ensuring precision comfort and superior balance.

- Smart Insoles with Embedded Sensors: Designed for fitness tracking, weight distribution, and rehabilitation data collection.

- Sustainable Material Innovations: Bio-based foams, flax-based fibers, and algae-infused gels are being developed as eco-friendly components.

- Medical Integration: Performance insoles are increasingly prescribed by orthopedic specialists to treat plantar fasciitis, flat feet, and chronic knee pain.

- E-commerce Expansion: Many French suppliers have opened direct online B2B channels, creating global accessibility for distributors and wholesalers.

Choosing a French supplier ensures high performance, reliability, and long-term product value. The advantages include:

- European quality and compliance with strict certification standards.

- Access to innovation-driven production processes.

- Experienced teams in ergonomic design and footwear engineering.

- Transparent pricing and delivery schedules.

- Established reputation among global footwear leaders.

For brands that prioritize product differentiation and comfort excellence, working with French factories is a key strategic investment.

As digital innovation and sustainability continue shaping global footwear production, the role of Performance Insoles Manufacturers And Suppliers will expand even further. Automated machinery, AI-assisted production, and nanotechnology are driving new levels of comfort and responsiveness in insole products.

Moreover, the integration of smart applications—capable of analyzing gait efficiency, calorie burn, and training optimization—signals a new era for intelligent footwear. Governments in Europe are also supporting green transitions in manufacturing, fueling research into recyclable polymers and bio-based resins.

Ultimately, the French insole sector is expected to maintain its reputation for excellence while deepening collaborations with international OEM partners, particularly in Asia and North America.

France stands as a leading force in the global insole industry, combining innovation, comfort, and sustainability. Through advanced design, certified production, and responsible practices, Performance Insoles Manufacturers And Suppliers in France have established a trusted reputation among international footwear brands and wholesalers.

By collaborating with French manufacturers, global businesses can access premium-quality products that embody precision engineering, long-lasting comfort, and eco-conscious craftsmanship. Whether your market focus is sports, orthopedic, or everyday footwear, sourcing insoles from France ensures durability, brand credibility, and exceptional performance for end users.

Contact us to get more information!

French manufacturers emphasize biomechanics, precision design, and certified materials. Their insoles offer a scientific foundation that enhances posture correction, impact absorption, and lasting comfort.

Yes. Most Performance Insoles Manufacturers And Suppliers provide OEM and ODM services, allowing brands to customize size, thickness, material composition, logo, and packaging configurations.

Many French companies now use sustainable practices—recycled EVA, natural cork, bio-based foams, and biodegradable packaging—to meet the growing global demand for eco-responsible footwear components.

Brands should request audit documentation, ISO certifications, and material compliance reports. In-person or virtual factory inspections provide transparency and ensure consistent production quality.

Absolutely. Many French brands design premium insole prototypes domestically and collaborate with Chinese manufacturers for high-volume production while maintaining European quality and testing standards. This hybrid model enhances efficiency and affordability.