Views: 222 Author: Edvo Publish Time: 2026-02-07 Origin: Site

Content Menu

● The Growing Market of Performance Insoles

● Understanding Performance Insoles Technology

● Top Performance Insoles Manufacturers And Suppliers in America

>> 1. Superfeet Worldwide Inc. (Washington)

>> 2. Dr. Scholl's Performance Division (Illinois)

>> 3. OrthoLite (Massachusetts)

>> 5. Spenco Medical Corporation (Texas)

● The Advantages of OEM Partnerships

● Why Collaborating With Chinese Insoles Manufacturers Makes Sense

● How to Choose the Right Performance Insoles Supplier

● Supply Chain Integration in the Footwear Industry

● Innovations Driving the Future of Performance Insoles

● Sustainability Initiatives in Insole Production

● Building Long‑Term OEM Success

● FAQ About Performance Insoles Manufacturers And Suppliers

>> 1. What are the main benefits of performance insoles?

>> 2. How do I find reliable Performance Insoles Manufacturers And Suppliers?

>> 3. Why do brands outsource to OEM insole manufacturers in China?

>> 4. What materials provide the best combination of comfort and durability?

>> 5. How is the insole market expected to evolve in the next five years?

In today's competitive footwear market, performance insoles are no longer an optional accessory—they're a strategic component of comfort, health, and brand differentiation. From running shoes and hiking boots to workwear and medical orthotics, performance insoles improve balance, absorb shock, and support natural motion.

As global demand continues to rise, many companies are turning to the leading Performance Insoles Manufacturers And Suppliers in America and beyond to produce ergonomic, durable, and sustainable products. This article explores the top players, market trends, OEM opportunities, and how choosing the right manufacturer can elevate your brand's success.

The market for performance insoles is evolving rapidly, propelled by growth in both sports and wellness sectors. Consumers now expect footwear that provides measurable benefits—reducing fatigue, enhancing posture, and preventing injuries.

Several key factors drive this expansion:

- Health awareness: Increasing focus on foot health has made orthotic and supportive insoles mainstream products.

- Sports technology: Athletes and trainers are emphasizing biomechanically engineered insoles for better performance.

- E‑commerce growth: Online customization and direct‑to‑consumer brands have accelerated demand for replacement insoles.

- Sustainability initiatives: Environmental concerns push manufacturers to explore degradable materials and eco‑friendly production methods.

According to recent market analyses, North America continues to lead global innovation in this area, driven by both local production and international collaborations with specialized Asian Performance Insoles Manufacturers And Suppliers.

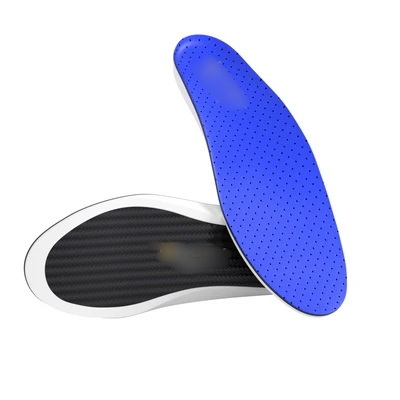

Modern performance insoles are the result of combined materials science, biomechanics, and engineering. The value of a high‑quality insole comes from its design layers and manufacturing precision.

1. Top fabric layer – Breathable and antimicrobial materials help maintain dryness and reduce odors.

2. Cushioning layer – Generally made of EVA, PU, or gel compounds for maximum comfort and durability.

3. Support base – Precision‑shaped layers reinforce the arch and heel, improving posture and alignment.

4. Outsole insert – Provides stability and friction control inside the shoe, especially during high‑impact activities.

Leading Performance Insoles Manufacturers And Suppliers continuously experiment with new foam densities, recycled rubber, and carbon‑fiber reinforcement. These materials help reduce foot strain while maintaining structural integrity under long‑term compression.

For instance, eco‑insoles now use plant‑based polyurethane derived from castor oil—offering resilience without relying on petrochemicals. Such advancements illustrate how technology enhances both sustainability and performance.

Superfeet combines decades of podiatric research with high‑performance design. Its product line covers orthotic and athletic segments. The company's commitment to precision fitting has earned a strong reputation among athletes and outdoor enthusiasts. With advanced 3D‑printing and CAD modeling, Superfeet remains an industry benchmark for quality and customization.

Founded over a century ago, Dr. Scholl's is synonymous with footcare. The modern performance division integrates biomechanics with mass manufacturing efficiency, offering insoles for walking, running, and workwear. Their R&D centers focus on comfort optimization and energy return, making them one of the most trusted Performance Insoles Manufacturers And Suppliers in the U.S.

OrthoLite is a global leader supplying insole technology to major shoe brands such as Adidas, Nike, and New Balance. It's particularly known for using eco‑friendly foams with up to 5% recycled rubber content and 20% bio‑oil base materials. Through its U.S. innovation hub, OrthoLite continues to push the limits of sustainable insole technology.

Powerstep focuses on podiatrist‑designed insoles that blend medical accuracy with athletic performance. Their double‑layer cushioning systems target both consumers and OEM clients. With flexible production capabilities and strong distribution networks, Powerstep has positioned itself as a reliable supplier for custom and branded projects.

Spenco stands at the crossroads of medicine and performance footwear. Its insoles are designed to reduce impact stress and enhance comfort for professionals, athletes, and patients with orthotic needs. In addition to their domestic market, Spenco collaborates with international footwear producers, demonstrating significant export expertise among Performance Insoles Manufacturers And Suppliers.

Many American footwear brands collaborate with specialized OEM manufacturers around the world, especially in China, to achieve scalable production and cost efficiency while maintaining top‑tier performance standards. Partnering with a trustworthy OEM insole manufacturer provides several advantages:

- Scalable production: Rapid capacity expansion for seasonal demand peaks.

- Competitive pricing: Reduced labor and material costs make products more affordable for global distribution.

- Flexibility in design: OEM partners often support logo printing, packaging customization, and multi‑density material selection.

- Quality assurance: Reputable OEM factories follow international standards like ISO9001, SGS, and REACH certification.

A seasoned OEM partner can transform prototypes into fully market‑ready products while maintaining strict confidentiality and consistency.

Chinese factories have evolved from simple producers to world‑class Performance Insoles Manufacturers And Suppliers offering full design, tooling, and manufacturing services. Their strengths include:

- Advanced machinery: Precision molding, 3D printing, and CNC cutting for accuracy.

- Dynamic R&D teams: Continuous material testing and functional analysis.

- Sustainable production: Many manufacturers now integrate recycling systems to minimize waste.

- Global logistics: Established export channels ensure timely delivery worldwide.

Our company, for instance, operates as a leading Chinese insole manufacturer providing end‑to‑end OEM and ODM solutions. We specialize in high‑performance sports insoles, orthopedic pads, and industrial footbeds. By merging engineering expertise with flexible production, we help international brands bring ergonomic, cost‑effective products to market faster.

Knowing which partner matches your brand's needs is essential. The right Performance Insoles Manufacturers And Suppliers should meet both technical and business expectations.

1. Experience and specialization – Choose manufacturers with proven expertise in high‑performance sports or orthotic insoles.

2. Material quality – Verify source stability and durability of compounds used.

3. Customization capabilities – Ensure they can produce unique molds and branding.

4. Compliance and ethics – Prioritize suppliers with safe, environmentally responsible facilities.

5. Production lead time – Reliable suppliers consistently meet deadlines.

6. Communication efficiency – Seamless collaboration between design and production reduces misunderstandings and delays.

Establishing long‑term relationships with skilled suppliers provides consistent support for product innovation and brand reputation.

Performance insoles are rarely produced in isolation—they're integral components in complex global supply chains. Successful partnerships among Performance Insoles Manufacturers And Suppliers depend on seamless coordination between material providers, designers, and distributors.

Many brands now adopt vertical integration models to control every stage from design to post‑sale service. Others prefer modular outsourcing, contracting specialized manufacturing partners for insoles, soles, and uppers separately. Both approaches aim to balance quality control with production agility.

For instance, when an American footwear brand partners with an experienced Chinese OEM insole factory, CAD files and prototypes can be shared digitally, shortening development cycles while ensuring international consistency in quality.

The next generation of insoles is not only about comfort but also about connectivity and intelligent materials. Several emerging trends are shaping future production:

- Smart sensor integration: Embedded chips can track pressure points and gait patterns in real time.

- 3D‑printed customization: On‑demand insoles are being developed for specific foot shapes using digital scanning.

- Temperature regulation: Phase‑change materials adapt to body heat for better thermal comfort.

- Bio‑based foams: Replacing petroleum with castor or algae oils reduces the carbon footprint.

- Advanced antimicrobial treatments: Silver ion technology prevents odor and bacterial growth throughout the insole's life.

These innovations demonstrate how Performance Insoles Manufacturers And Suppliers continue to blend science, design, and environmental consciousness.

Sustainability plays a larger role each year in manufacturing strategies. Many American and Chinese producers are shifting toward a circular economy model. Typical actions include:

- Using recycled EVA waste to manufacture new insoles.

- Reducing water and chemical consumption in foam molding.

- Implementing closed‑loop recycling for returned or defective products.

- Introducing biodegradable packaging and minimal plastic wrapping.

Brands that emphasize green production not only attract eco‑conscious consumers but also strengthen long‑term competitiveness.

Whether producing for sports brands, workwear manufacturers, or orthotics distributors, effective collaboration requires mutual trust. Performance Insoles Manufacturers And Suppliers that communicate transparently, maintain consistent quality, and deliver innovative materials tend to form the strongest industry partnerships.

When brands and factories work hand‑in‑hand—from concept sketches to final quality checks—they achieve faster market entry, reduced production costs, and superior design fidelity. This synergy defines the evolving landscape of global footwear manufacturing.

The market for performance insoles highlights the ongoing fusion of technology, comfort, and sustainability in modern footwear. The leading Performance Insoles Manufacturers And Suppliers in America—such as Superfeet, Dr. Scholl's, OrthoLite, Powerstep, and Spenco—set strong technical benchmarks for innovation.

At the same time, global collaboration with experienced OEM producers from China enables brands to expand product portfolios efficiently and cost‑effectively. Together, these partnerships ensure that consumers worldwide enjoy shoes that not only feel great but also perform under the toughest conditions.

For brands entering this field or optimizing existing supply chains, the future lies in smart manufacturing, eco‑friendly materials, and collaborative OEM development that merges creativity with precision engineering.

Contact us to get more information!

Performance insoles enhance comfort, stability, and foot alignment. They reduce pressure on joints, prevent fatigue, and improve energy return during physical activity, making them essential for athletes, workers, and everyday users.

Start by researching companies with proven experience, ISO certifications, and excellent reviews. Request material samples, compare pricing structures, and check for OEM/ODM capabilities before signing a contract.

OEM partnerships help reduce production costs while maintaining quality standards. Chinese factories offer advanced design support, rapid prototyping, and flexible customization options suited to global footwear brands.

EVA, PU, and gel foams are the most common materials for cushioning, while carbon fiber or TPU shells provide lasting structural support. Selecting the right material mix depends on performance requirements and target markets.

Experts predict stronger growth in eco‑based foams, 3D‑printed custom models, and smart insoles with biometric tracking. Demand for sustainable and personalized products will shape future innovation strategies among Performance Insoles Manufacturers And Suppliers.