Views: 222 Author: Edvo Publish Time: 2026-02-09 Origin: Site

Content Menu

● Understanding Performance Insoles and Their Importance

● Market Overview: The UK Insole Industry on the Rise

● Leading Performance Insoles Manufacturers and Suppliers in the UK

>> Enertor Performance Insoles

>> Our China-Based OEM Insole Factory

● Cutting-Edge Materials and Technologies

● Why OEM and ODM Partnerships are Advantageous

● The Growing Demand for Medical and Orthopedic Insoles

● Sustainability: Driving the Future of Insole Manufacturing

● Challenges and Opportunities in the UK Market

● Why UK Brands Should Collaborate With Overseas Manufacturers

● FAQ

>> 1. What are performance insoles and why are they important?

>> 2. How can UK brands benefit from working with overseas manufacturers?

>> 3. What materials are most commonly used for making insoles?

>> 4. Are sustainable insoles becoming more popular in the UK?

>> 5. How can brands ensure quality when outsourcing manufacturing?

The United Kingdom's footwear market is evolving rapidly, driven by growing consumer awareness of foot health, lifestyle comfort, and performance footwear innovation. Today, footwear is more than just fashion—it's a fusion of comfort, technology, and function. In this context, Performance Insoles Manufacturers and Suppliers play a crucial role in meeting the needs of both athletes and everyday users seeking enhanced comfort, injury prevention, and long-lasting support.

As one of China's leading insole producers, our company specializes in OEM and ODM manufacturing services for international brands, wholesalers, and producers across the UK and Europe. This article explores the leading Performance Insoles Manufacturers and Suppliers in the UK, uncovers new industry trends, key technologies, and materials, and offers valuable insights for businesses looking to expand their presence through OEM collaboration.

Performance insoles are specialized footwear inserts designed to optimize comfort, posture, and athletic ability. They provide the foundation for better biomechanics, joint protection, and muscle balance—factors that contribute directly to performance and overall well-being.

A well-crafted performance insole can:

- Absorb shocks during running, walking, or heavy-duty work.

- Support foot arches and align lower limbs properly.

- Reduce fatigue in long hours of standing and prevent repetitive stress.

- Minimize injuries caused by improper gait mechanics or flat feet.

- Improve efficiency in movement by stabilizing each step.

For professional athletes and everyday users alike, this product category has become indispensable. As more consumers invest in sports, healthcare, and comfort-oriented shoes, Performance Insoles Manufacturers and Suppliers continue innovating through design precision and cutting-edge materials.

The UK's sportswear and wellness markets have expanded significantly over the past decade. As consumers adopt active lifestyles and prioritize orthopedic health, insoles have become an essential footwear component. Reports show that demand for ergonomically designed and eco-friendly insoles has been rising steadily, with an annual growth rate surpassing 6% in recent years.

Key drivers of this momentum include:

- A sharp rise in sports participation, particularly running, basketball, and hiking.

- Increasing use of smart and orthotic footwear by healthcare institutions.

- Expansion of e-commerce channels selling personalized comfort products.

- Aging populations seeking better walking stability and joint protection.

- Competitive innovation among Performance Insoles Manufacturers and Suppliers in Europe and Asia.

The market is competitive yet full of opportunities for business collaboration, private labeling, and cross-border OEM partnerships.

The UK insole manufacturing sector combines deep technical expertise with strong consumer trust. Below are several noteworthy Performance Insoles Manufacturers and Suppliers that define the current market landscape.

Sorbothane is one of the longest-standing names in shock absorption technology. It produces advanced insoles that combine comfort and protection using its proprietary viscoelastic material. Favored by athletes and the British military, Sorbothane's insoles minimize impact stress while maintaining consistent energy return. Over the years, they've established themselves as a global benchmark in support and endurance.

Superfeet is a global brand with deep roots in biomechanical design. Its UK operation focuses on innovation, sustainability, and expert fitting. The company's insoles are crafted based on podiatric science, offering targeted arch structures for different sports and daily wear. With recyclable packaging and eco-driven materials, Superfeet is among the most committed Performance Insoles Manufacturers and Suppliers supporting the UK's sustainability agenda.

Originally from Finland, Footbalance has expanded throughout the UK through retail and online partnerships. Their standout feature is custom-molded 3D insoles that adapt to each user's foot profile. Using digital scanning technology, Footbalance provides the perfect balance between comfort and orthopedic correction, making it an ideal solution for both sports and medical footwear retailers.

Endorsed by Olympic sprinter Usain Bolt, Enertor stands out for its patented D3O® impact protection technology. The company's insoles offer up to 40% shock absorption and optimal energy transfer—critical for high-impact athletes. Furthermore, Enertor collaborates extensively with healthcare professionals, making it a hybrid sports and medical brand bridging science and performance footwear.

While many UK brands maintain local R&D and branding, their large-scale production often relies on collaboration with overseas Performance Insoles Manufacturers and Suppliers for competitive pricing and advanced customization. As one of China's leading insole producers, our factory provides tailor-made OEM and ODM services for global brands.

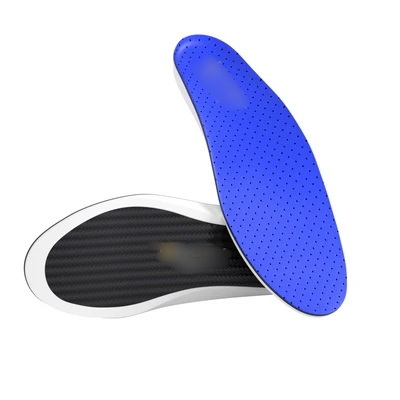

We specialize in EVA, PU, gel, and carbon fiber insoles, built with automated CNC molding and precise lamination processes to ensure uniform quality. Our production flexibility allows us to meet both bulk orders for wholesalers and high-end customized projects for brand clients. By cooperating with UK distributors, we combine local design insights with the manufacturing efficiency and quality assurance of modern Chinese production.

Modern consumers expect both comfort and longevity from their insoles. The best Performance Insoles Manufacturers and Suppliers invest heavily in advanced materials and modern production techniques, such as:

- EVA (Ethylene-Vinyl Acetate): Known for exceptional cushioning and lightweight flexibility.

- PU Foam (Polyurethane): Resilient and ideal for heavy-duty or industrial footwear.

- Gel & Silicone Layers: Enhance rebound and pressure dispersion over extended use.

- Carbon Fiber or TPU Plates: Add stiffness for high-energy return and stability.

- Memory Foam & Latex: Provide softness for luxury or therapeutic applications.

- Antibacterial Linings: Maintain freshness, prevent odor, and extend lifespan.

In addition, digital 3D foot scanning, pressure mapping, and automated cutting systems ensure precision fitting and reduce waste. These innovations allow manufacturers to deliver both mass-market and medical-grade products efficiently.

Working with experienced Performance Insoles Manufacturers and Suppliers abroad allows UK brands to scale efficiently while maintaining control over design, branding, and compliance. Some of the core benefits include:

- Cost efficiency: Access to high-quality production at globally competitive prices.

- Design flexibility: Infinite custom options including logo placement, colors, and structural layouts.

- Consistency: Strict quality control systems ensure repeatable standards across orders.

- Speed-to-market: Sophisticated factories shorten lead times through automation and logistics networks.

- Confidentiality and exclusivity: Secure contracts ensure product designs remain exclusive to your brand.

Partnering with a reliable Chinese factory eliminates manufacturing limitations while enabling brands to meet growing UK demand with premium, cost-effective insoles. Through transparent communication, factory audits, and digital design sharing, OEM partnerships now function as seamless global collaborations supporting long-term brand development.

While lifestyle and sports applications drive most of the insole market, healthcare has become an equally vital segment. Orthopedic and medical insoles, often prescribed by podiatrists, help treat flat feet, plantar fasciitis, and joint misalignment.

Performance Insoles Manufacturers and Suppliers catering to this field have expanded their expertise to include:

- Thermo-moldable materials that adapt to the wearer's anatomy.

- Corrective heel cups for pronation control.

- Pressure-relief zones to prevent diabetic ulcers.

- Custom orthotics developed using digital gait analysis.

This medical-grade evolution has broadened the market's boundaries. Today, brands combining medical insight with high-performance materials are dominating both retail and professional sectors.

Sustainability is no longer optional—it's essential. Consumers are increasingly choosing products that are safe for both their feet and the planet. Many leading Performance Insoles Manufacturers and Suppliers now integrate sustainability into every production stage.

Key eco-conscious practices include:

- Using recycled EVA, TPU, or bio-based foams derived from renewable sources.

- Applying water-based adhesives instead of solvent-based glues.

- Incorporating biodegradable packaging to reduce plastic waste.

- Implementing ISO 14001-certified production systems to minimize emissions.

Our factory is committed to these practices. By reclaiming scrap materials, reducing energy use through solar integration, and offering fully recyclable packaging, we help international partners align with Europe's strict environmental standards while maintaining durability and affordability.

Despite steady growth, Performance Insoles Manufacturers and Suppliers face several challenges: tight regulatory compliance, rising labor costs, and increasing competition from digital-fitting startups. However, these challenges bring equal opportunities for innovation.

Some of the promising strategies include:

- Developing insoles with smart sensors for real-time gait tracking.

- Expanding e-commerce personalization tools allowing buyers to select arch types and fit levels online.

- Integrating British design creativity with Asian production capacity for hybrid partnerships.

- Expanding B2B collaboration with sportswear, medical footwear, and retail chains.

With strong supply chain coordination and product differentiation, the insole industry's growth potential in the UK remains enormous.

For medium and large-scale footwear brands, outsourcing production to expert Performance Insoles Manufacturers and Suppliers provides several long-term benefits. Manufacturing partners like ours offer modern workshops, R&D teams, and consistent performance testing, all while reducing domestic operational costs.

Moreover, Chinese manufacturing partners provide:

- Rapid prototyping for updated seasonal lines.

- Custom graphic branding for private label differentiation.

- Packaging design support aligned with UK marketing preferences.

- Seamless bulk export logistics directly to UK ports.

This model empowers fashion, sports, and healthcare segments to remain competitive while focusing internal resources on innovation, distribution, and customer experience.

The rise of Performance Insoles Manufacturers and Suppliers in the UK highlights how science, design, and comfort have merged to redefine footwear. Whether through local innovators like Sorbothane and Superfeet or trusted OEM partners in China, the insole industry continues to provide smarter, more sustainable, and personalized solutions for global consumers.

For brands and retailers, the key to success lies in selecting manufacturing partners that combine quality craftsmanship with advanced materials, eco-conscious production, and responsive OEM service. By aligning creativity with technology, both UK and international companies are paving the way for a more comfortable, high-performance future in footwear manufacturing.

Contact us to get more information!

Performance insoles are specialized footbeds that improve comfort, posture, and energy return during activities. They are essential for minimizing impact, improving stability, and boosting sports and daily performance.

Collaborating with overseas Performance Insoles Manufacturers and Suppliers allows UK brands to lower production costs, access advanced materials, and scale manufacturing without sacrificing product quality.

Manufacturers often use EVA, PU, gel, memory foam, and TPU for cushioning, flexibility, and durability. Each material can be fine-tuned based on the intended shoe type and performance requirement.

Yes. UK consumers are prioritizing eco-friendly options, and many manufacturers now use recycled or bio-based foams, water-based adhesives, and recyclable packaging to reduce environmental impacts.

Reliable partners follow ISO-certified production, conduct strict quality inspections, and provide pre-shipment reports. Consistent sampling, lab testing, and communication ensure every batch meets brand standards.